- Home Page

- Company Profile

-

Our Products

- Industrial Gasket

- EPDM Gasket

- Spiral Wound Metallic Gasket

- Spiral Gasket

- Corrugated Metal Gasket

- Rubber O Ring Gasket

- Automotive Gasket

- Solid Metal Gasket

- Carbon Graphite Gasket

- Asbestos Gasket

- Ring Joint R-Octagonal Gasket

- PTFE Envelope Gasket

- EPDM Rubber Gasket

- Non Asbestos Gasket

- Ceramic Gasket

- CAF Gasket

- Envelope Gasket

- Oval Gasket

- Graphite Gasket

- Flat Metal Gasket

- Expansion Joint Gasket

- Flange Gasket

- PTFE Gasket

- Custom Gasket

- Metallic Gasket

- Seal Strip Rubber Gasket

- Laminated Gasket

- Exhaust Gasket

- Tapper Ring Gasket

- Serrated Metal Gasket

- Non-Metal Gaskets

- Camprofile Gaskets

- Spiral Wound Gaskets

- Ring Joint Gaskets

- Rubber Gaskets

- Extruded & Molded Gaskets

- Ceramic Fiber Gaskets

- Carbon & Graphite Gaskets

- Metal Shims

- O Rings

- Expansion Joints

- Hylam Rod

- Metal Gaskets

- Insulated Sheet

- PTFE & PTFE-Based Gaskets

- CAF and NACF Cut Gasket

- Metal Jacketed Gasket

- PTFE Envelope Gaskets

- PTFE Gasket

- Rubber Gasket

- Spiral Wound Gasket

- Graphite Gasket

- Kammprofile Gasket Manufacturers

- Solid Gasket

- Ceramic Gaskets

- Ring Type Joint Gasket

- Corrugated Metallic Gaskets

- Hylum-bakelite Fabricated Insulation Kit Gaskets

- Asbestos & Non Asbestos Gland Packing

- ASBESTOS ROPS CLOTHS AND ETC

- CAF & NONASBESTOS GASKET

- COPPER GASKET

- G TYPE GASKET

- INSULATING KIT

- JACKETED GASKET

- MILBOARD GASKET

- PTFE ENCAPSULATED VITON O RING

- PTFE PRODUCTS

- RUBBER PRODUCTS

- SERRATED GRAPHITE GASKET

- SS CORRUGATED GASKET

- Industrial Gasket

- Gallery

- Contact Us

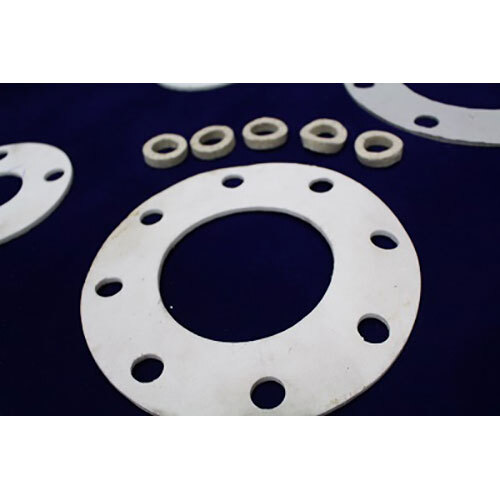

Ceramic Gaskets

100.0 INR/Piece

Product Details:

- Standard Industrial

- Working Temperature 1050 Celsius (oC)

- Hardness Low Hardness

- Medium Gas

- Usage Industrial

- Material Felt

- Shape Ring Gasket

- Click to view more

X

Ceramic Gaskets Price And Quantity

- 1 Number, Number, Number

- 100.0 INR/Piece

Ceramic Gaskets Product Specifications

- Gas

- Low Hardness

- Felt

- High Temperature Industries majorly used in Petro chemical and Gas industries

- 1050 Celsius (oC)

- Industrial

- Industrial

- Ceramic Gasket

- White

- Available in All Customized Sizes

- Ring Gasket

Ceramic Gaskets Trade Information

- Gujarat

- 6000-7000 Number, Number, Number Per Day

- 2 Days

- Yes

- Contact us for information regarding our sample policy

- South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia, Central America, North America

Product Description

For applications needing high-temperature resistance, SP Gasket & Packing is a top supplier of high-temperature ceramic gaskets and materials. Applications requiring temperatures up to 2300F can benefit greatly from the great adaptability of ceramic fibre material. We can create custom gaskets that are perfect for your boiler, furnace or other high-temperature project using rolls of this material that we sell in a range of thicknesses. Through a rigorously regulated high temperature furnace melting and fiberising process, we provide SPGASKET Ceramic Fibre, which is made from high purity aluminosilicate material.

Applications for Ceramic Fibre Types:

- Insulating gaskets and seals at high temperatures

- Protective blankets, drapes, covers, pads, and wraps

- Safety clothes and expansion joint fabric

What advantages can ceramic gaskets offer?

- Resistance to temperature and chemicals

- Resistance to wear

What are common applications for ceramic gaskets?

- Insulation covers

- Annealing lines

- Petrochemical heaters

- Expansion joints

- Door seals

| Product Name | Ceramic Fiber Gasket | |

| Temperature() | 1260 | |

| Max Operation Temp()/() | 1050(1922) | |

| Density(kg/m3) | ||

| Tensile Strength(Mpa) | >0.4 | |

|

Chemical Composition

|

Al2O3 | 42 |

| Al2O3+SiO2 | 97 | |

| ZrO2 | - | |

| Fe2O3 | 1 | |

| Na2O+K2O | 0.5 |

Product Specifications :

|

Product Name |

Standard Ceramic Fiber Gasket |

High-Alumina Ceramic Fiber Gasket |

Zirconia Ceramic Fiber Gasket |

|

|

Temperature( Degree C) |

1260 |

1400 |

1450 |

|

|

Max Operation Temp( Degree C)/(Degree F) |

1050 Degree C(1922 Degree F) |

1200 Degree C(2192 Degree F) |

1350 Degree C(2462 Degree F) |

|

|

Density(kg/m3) |

20010 |

|||

|

Tensile Strength(Mpa) |

0.4 |

0.4 |

0.7 |

|

|

Chemical Composition |

Al2O3 |

42 |

52-55 |

39-40 |

|

Al2O3+SiO2 |

97 |

99 |

- |

|

|

ZrO2 |

- |

- |

15-17 |

|

|

Fe2O3 |

1.0 |

0.2 |

0.2 |

|

|

Na2O+K2O |

0.5 |

0.2 |

0.2 |

Specifications :

|

Specification(mm) |

40000x610x0.6 ; 40000x610x1 ; 20000x610x2 ; 15000x610x3 ; 10000x610x5 ; 10000x610x6 |

|

Min Width |

5cm |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email